Craftsman Drill Press Parts Diagram Wiring Service

CRAFTSMAN CRAFTSMAN 13" DRILL PRESS Parts Model 113213130 Sears PartsDirect

When starting a hole, drill it a bit undersized. Drive the reamer at a slow, constant speed. 1. The cutting speed for reaming should be about 1/3 of the speed used for drilling operation of the same material. 2. Before reaming, leave about .010" of material on holes up to 1/2", and about .020" of material on larger holes. 3.

Delta Drill Press 11120

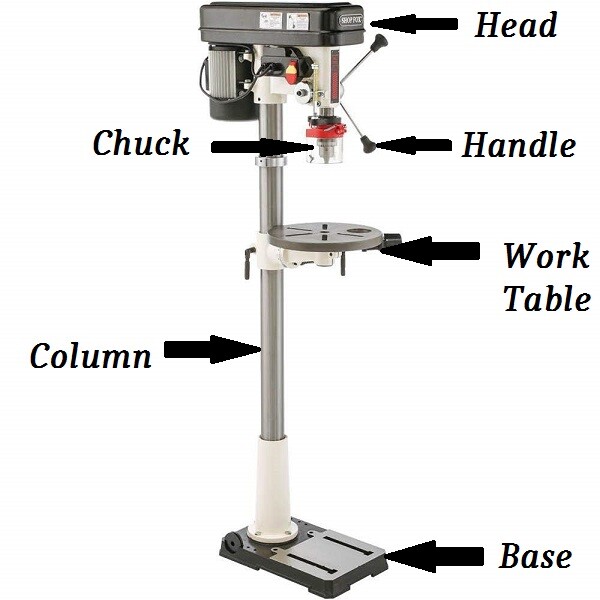

The head of the drill press holds other components such as the spindle, the chuck, the drill bits, and the control lever. The drill press's motor is also housed directly below the head. It's like the brain that holds everything in place. The head may also allow for lateral movement in order to change the position of the spindle.

Delta Drill Press Parts List Reviewmotors.co

The spindle is the most crucial part of a drill press. It is fixed at the bottom of the head, and it spins in circles to be able to drill holes. • Sleeve (or Quill) The sleeve holds taper shank drills where the taper size equals the spindle. • Table. The drill press table is where the material being drilled is laid.

Dayton Drill Press Parts Diagram Reviewmotors.co

Parts of a Drill Press. If you're a DIY enthusiast or professional woodworker, having a drill press in your workshop is essential. Drill presses are powerful and versatile tools that can make your drilling tasks more accurate and efficient. To fully understand how a drill press operates, it's important to familiarize yourself with its.

CRAFTSMAN 10" DRILL PRESS Parts Model 137280070 Sears PartsDirect

It consists of several key parts, each with its own function and importance in the drilling process. 1. Base. The base of the drill press provides stability and support for the entire machine. It is typically made of heavy-duty cast iron or steel to ensure durability and minimize vibrations during operation. 2.

Craftsman 12434984 drill press parts Sears PartsDirect

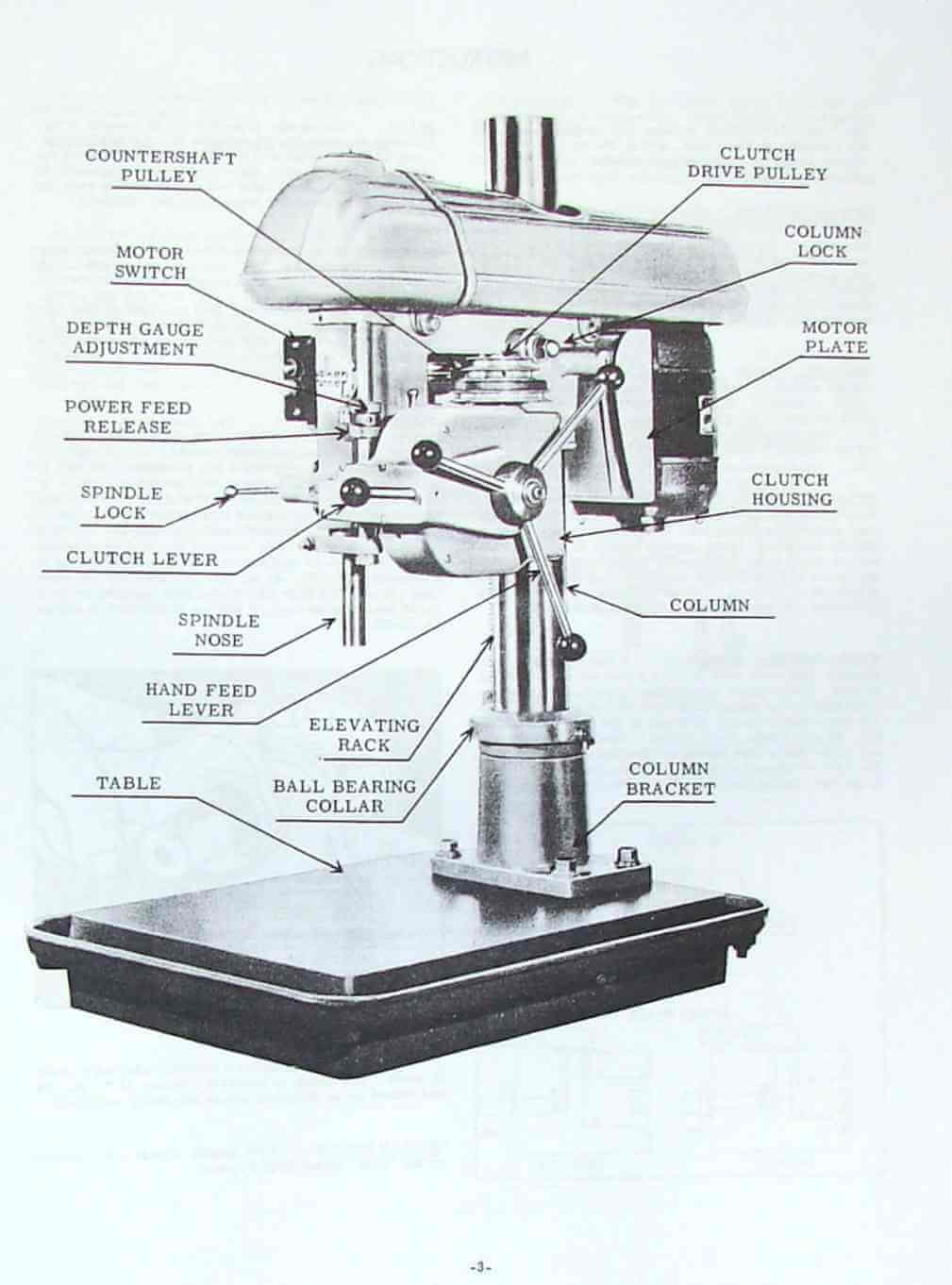

drill press diagram-parts of a drill press Source Drill Press Machine Parts and Functions 1. Head. The head is the part where the spindle resides. The head enables the spindle's vertical movement onto the workpiece. The head is responsible for adjusting the drill height, speed, and feeds. 2. Spindle

Parts of a Drill Press Explained With Diagram

It must be sturdy and precise for accurate drilling operation. 2. Head: The head part of the drill press houses the spindle at the top, responsible for moving the spindle upward or downward. Its primary function is to control the drill bit's depth and securely hold it in place during drilling.

CRAFTSMAN 8 INCH BENCH MODEL DRILL PRESS Parts Model 113213720 Sears PartsDirect

Unravel the mystery behind all drill press parts in this comprehensive guide! Discover the crucial components like the base, column, table, head, and more, essential for precise and stable drilling operations. Learn about additional features and accessories to boost functionality, maintenance tips to ensure longevity, and troubleshooting advice for seamless DIY projects.

Drill Press parts Diagram Quizlet

A typical drill press consists of several key parts, including the base, column, table, head, quill, chuck, and motor. The base provides stability, the column supports the head and motor, the table is where the workpiece rests, the head houses the motor and spindle, the quill moves up and down, the chuck holds the drill bit, and the motor provides power for the drill press.

Central Machinery Drill Press Property Room

10 Main Parts of a Drill Press Explained. 1. Base. The drill press base is generally cast iron since this heavy metal offers stability to the tool, even during heavy operation. Depending on the press's design and size, this base is mounted on a workbench, a pedestal, or floor. Floor-mounted machines tend to be heavier and are designed for.

Parts of the Drill Press Woodworking Machinery

The benchtop drill press is a compact and versatile option suitable for smaller projects and workshops with limited space. This type is often portable and can be easily moved around a workspace. Floor drill presses, on the other hand, are larger and more powerful machines that are ideal for heavy-duty tasks and industrial use.

Parts Of A Drill Press ubicaciondepersonas.cdmx.gob.mx

For metalworking applications, a tapping attachment enables the drill press to be used for creating threaded holes, offering greater flexibility for machining metal parts. Furthermore, a mortising attachment can transform a drill press into a mortising machine capable of cutting square or rectangular holes in wood, making it a versatile addition for woodworking enthusiasts.

Dayton Drill Press Parts Diagram Reviewmotors.co

These three drill press parts work in tandem to ensure every drill is accurate and to the desired depth. Motor, Pulleys, and Belts - Powering the machine. Anatomy of a Drill Press - Motor, Belt and Pulleys. Motor: The powerhouse of the drill press, converting electrical energy into mechanical motion.

Drill Press

By. Cassie Damewood. Drill bit speeds are adjustable. A drill press is a stationary drill that is secured by bolts to a workbench, floor or stand. It has five parts, including a base, table, column, spindle and drill head.

How To Use A Drill Press Step By Step How To Use A Drill Machine Basics to Know

Some drill presses have a speed chart that recommends the appropriate speed for different materials and drill bit sizes, simplifying the selection process. Additional Considerations for Drill Press Buyers. Now that we have covered the various parts of a drill press, let's explore some additional considerations to keep in mind when purchasing.

Central Machinery 34231 Drill Press Property Room

The main parts of a drill press include the base, column, table, spindle, chuck, and motor. The base provides stability, the column supports the spindle and motor, the table supports the workpiece, the spindle holds the chuck and drill bit, the chuck grips the drill bit, and the motor powers the spindle for drilling.